It is widely used in many industries such as mining, metallurgy, building materials, and chemicals, especially in production processes that require fine and ultra-fine crushing. Its castings mainly include key components such as moving cones, fixed cones, lining plates, and impact plates, which are subjected to strong impact, wear, and high-load operation in the equipment. High Efficient Energy Saving Crusher High manganese steel castings

It is particularly suitable for crushing materials with high hardness and strong abrasiveness, such as ore, quartz stone, granite, iron ore, etc. They can provide good crushing effect and particle size control in efficient fine-crushing equipment, ensure the crushing and grading effect of fine-grained materials, and at the same time reduce energy consumption and optimize production processes. Especially in application scenarios that require energy saving and consumption reduction and improve production efficiency, these high manganese steel castings can help enterprises reduce operating costs and improve comprehensive production benefits while ensuring crushing performance. They are key components for improving equipment performance and reducing maintenance costs in the fields of mining crushing, metallurgy smelting, and building materials.

High Efficient Energy Saving Crusher High Manganese Steel Castings Suppliers

information to be updated

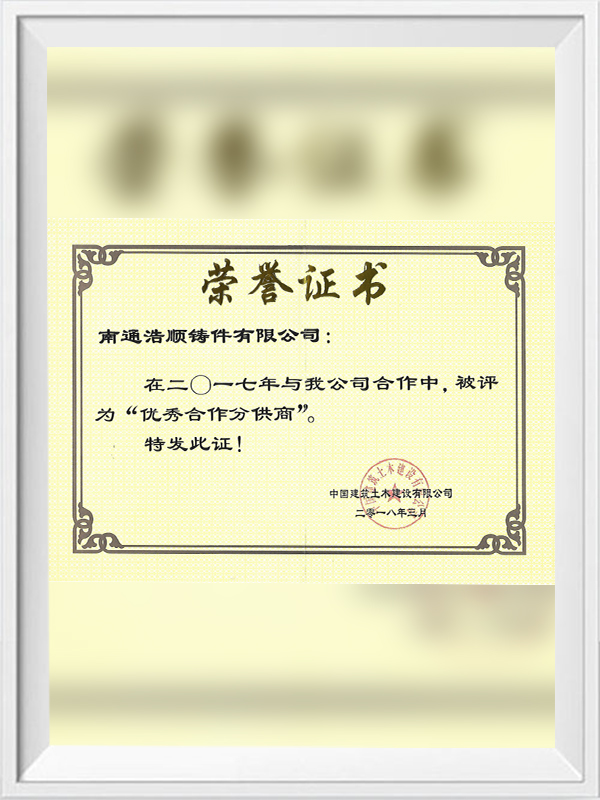

Nantong Haoshun Casting Co., Ltd. is a wholly-owned Taiwanese enterprise located in Wanghao Town, Haimen City, a land of fish and rice in the Jianghai Plain, on the northern wing of Shanghai. It is adjacent to Ningqi Expressway in the south, Provincial Highway 335 Tonglu Road and Tonglu Canal in the north, the world-famous Lushi Fishing Port in the east, and Nantong City and Nantong Airport in the west. The water and land transportation is very convenient. As a famous China High Efficient Energy Saving Crusher High Manganese Steel Castings Manufacturers and High Efficient Energy Saving Crusher High Manganese Steel Castings Suppliers, the company's main products include mining machinery and equipment such as crushers and accessories: high manganese steel jaw plates, liners, impact liners and hammers; high chromium wear-resistant jaw plates, plate hammers and hammers; chromium series wear-resistant cast iron grinding balls; chromium-molybdenum-niobium alloy steel liners, etc. The products are sold all over the country and exported to more than 10 countries and regions. The company has advanced production equipment, complete testing methods, strong technical force, and good product quality. The company meets the needs of new and old customers with a standardized management system, stable product quality, reliable integrity management, and professional customer service.

-

Why Are Cone Crusher High Manganese Steel Castings the Preferred Choice for Harsh Mining Operations?

How Does Alloy Composition Enhance the Performance of High Manganese Steel Castings? What makes the metallurgical makeup of Cone Crusher High Manganese Steel Castings so unique compared to standard steel? The secret lies...

-

In the demanding environment of mineral processing and aggregate production, the durability of wear parts determines the operational lifespan of the machinery. Among these components, Impact Crusher High Chromium Casting...

-

In the mining, quarrying, and resource recycling industries, the cone crusher serves as the core crushing equipment. Its production efficiency and operating expenses (OPEX) depend directly on the performance of its wear ...

English

English  русский

русский  عربى

عربى